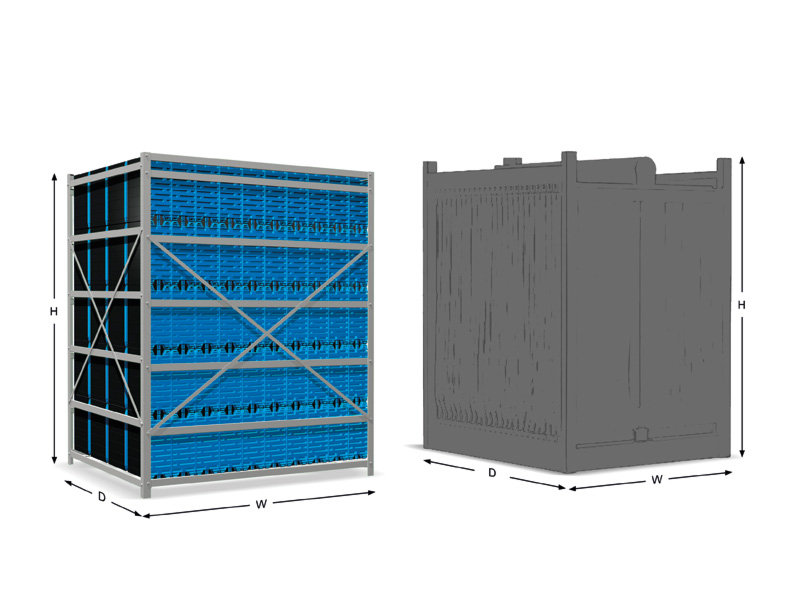

This is how the MicroClear system works

Click on the image to find out more about the benefits of the Microclear® filter housing.

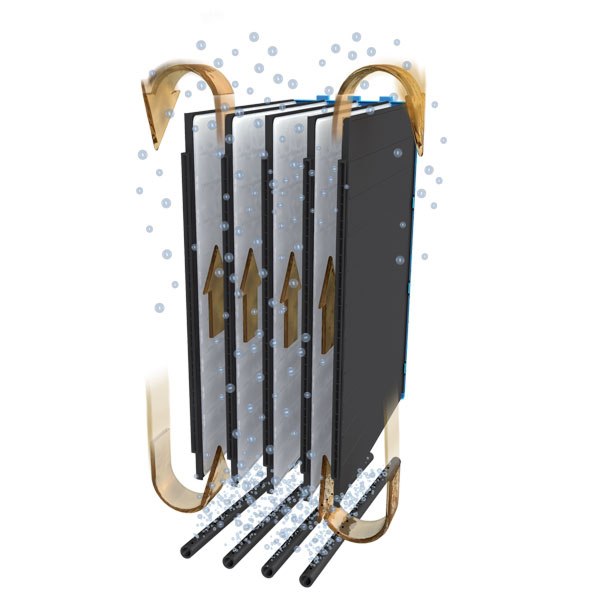

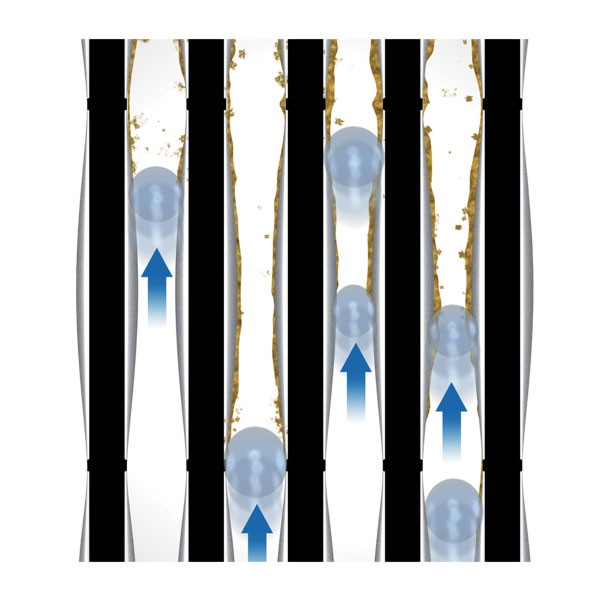

New, Optimized Aeration

- High cross-flow velocities are achieved

- Reduced air requirement of only 0.28 Nm³/m²h

- Optimized bubble size enhances cleaning performance

Submerged Membrane Technology with Crystal Clear Benefits

- Robust polypropylene plates with welded membranes on both sides

- Maximum retention of bacteria and viruses

- The useful life of the filters is up to 10 years

- Designed without the need for adhesives or seals

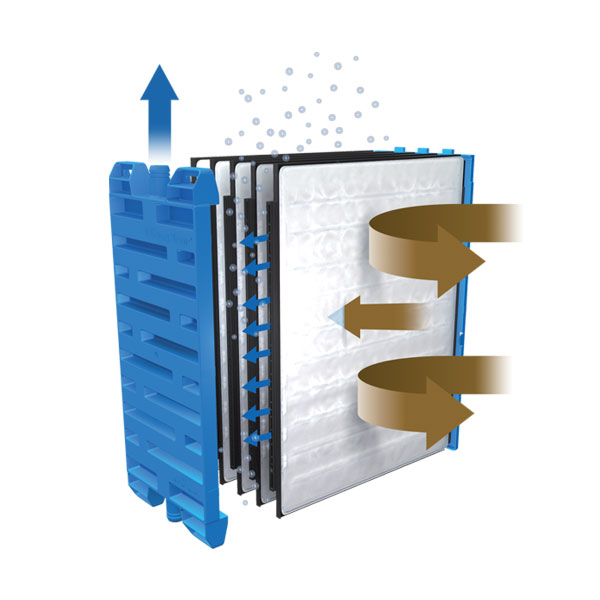

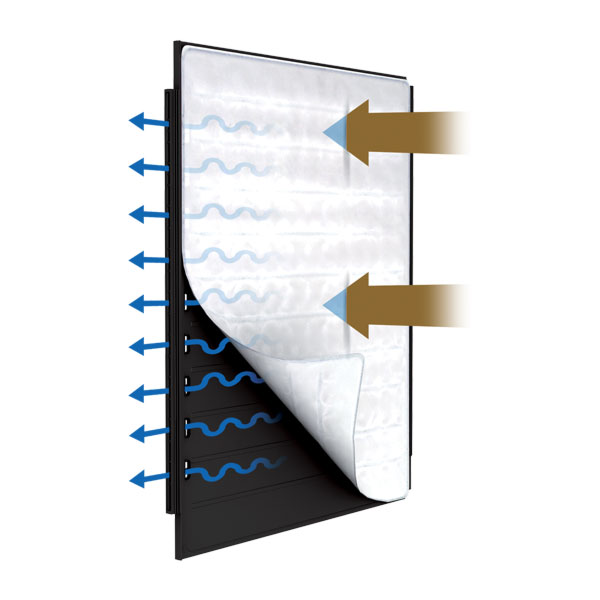

True Back Flush Capability

- Consistent, precisely defined spacing of the individual plates

- Extremely uniform distribution of flow and cleaning process

- MicroClear® filters can be completely back flushed

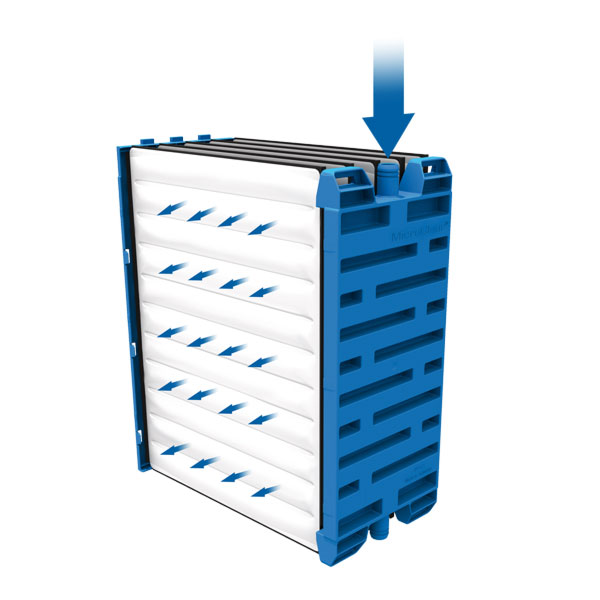

Removable closing plate

- Backplate for plate stabilizing

- Easy manteling and dismanteling

- Smart cleaning of each single flat sheet

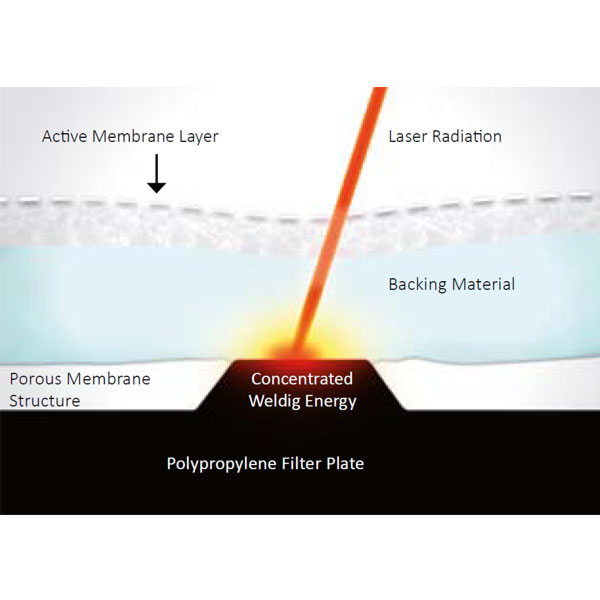

Innovative Laser Welding Process

- The membrane / filter plate unit delivers the highest structural integrity and long-term durability

- State of the art laser welding process

- Unlike conventional welding processes, ours does not destroy the membrane layer

Replacementproduct for hollow fiber installations

- Same package density as Hollow Fiber Modules of 185 m²/m³

- Less maintenance effort

- Smaller total costs of ownership

- Same energy consumption

Uniform Pressure Distribution

- Patented design with multiple filtrate outlets

- Uniform pressure distribution over the entire surface of the membrane

- The formation of partial surface layers is prevented

Cleaning without Chemicals

- Carefully defined bubble size cleans the membrane surfaces

- Simultaneous addition of oxygen into the activated sludge is ensured

- The need for chemical cleaning is kept to an absolute minimum